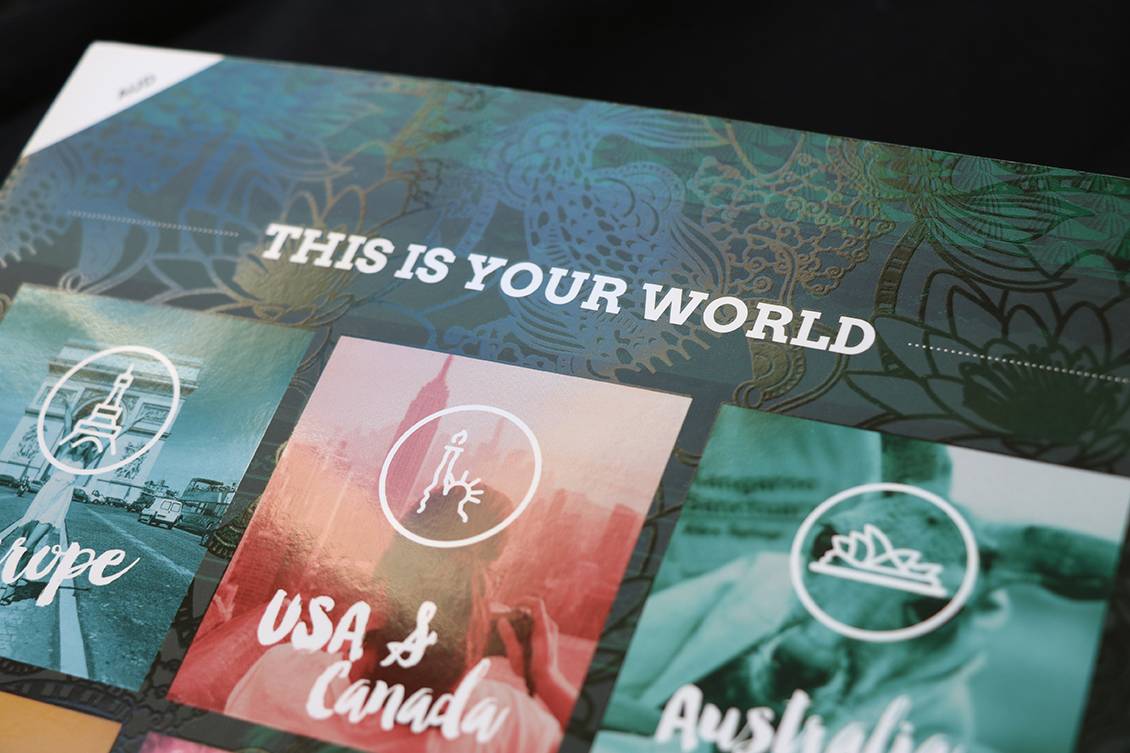

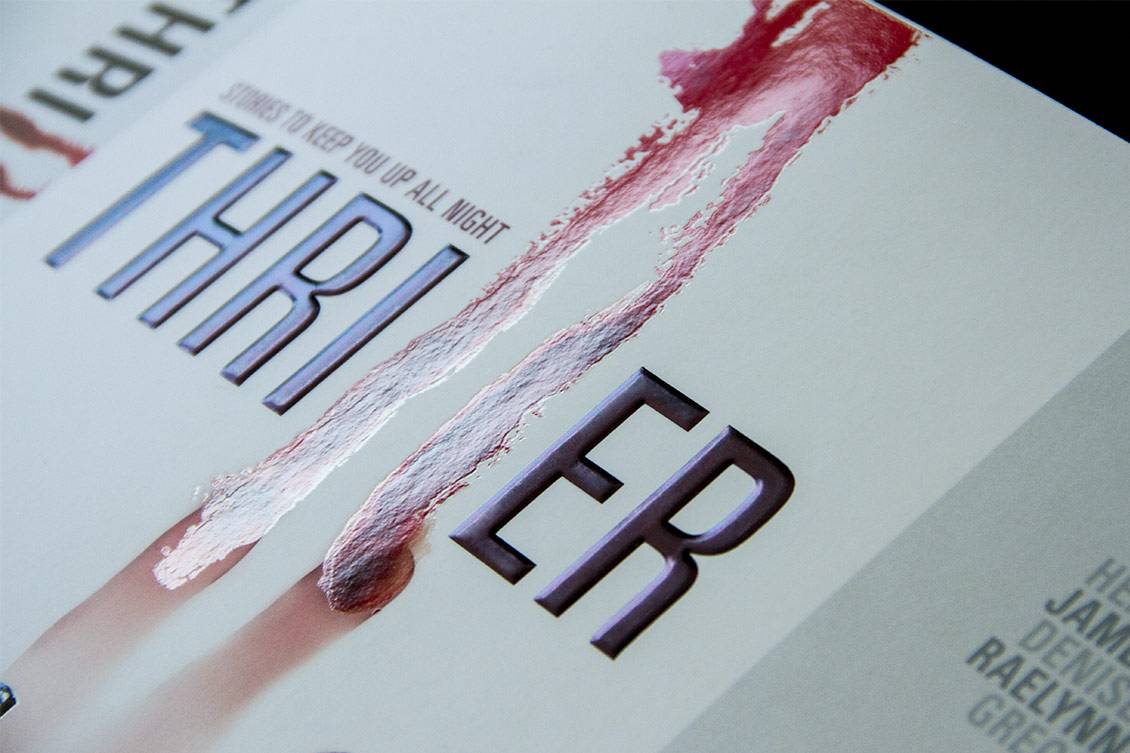

SpotKote allows your designing mind to go free by Spot coating with high gloss or matt to highlight logos, panels, special graphics and designs. Anything is possible. A stunning way of adding a Spot gloss or a Spot matte to complement your design and because it’s applied by screen you have the control. There is no comparison to a silk screen SpotKote as machine varnish’s, aqueous coatings and dry trap varnishes pale into significance when compared to screen spot work, don’t be fooled there is only one SpotKote.

Adding a clever pattern, stripes, waves, circles or even SpotKote a message on a dark colour background your options are waiting for you. For that extra finishing touch why not try adding MatteKote, TouchKote or ToughKote before we SpotKote. Then again why not add FoilKote or an emboss or deboss, let us help you with your next project.