About This Project

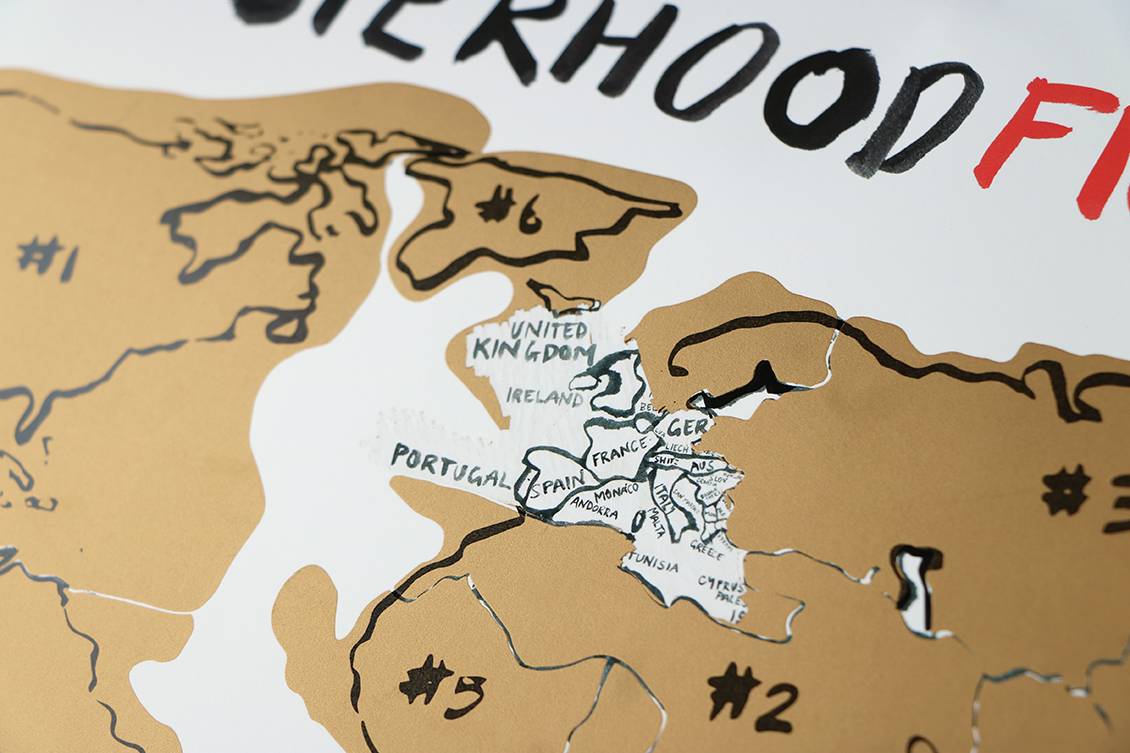

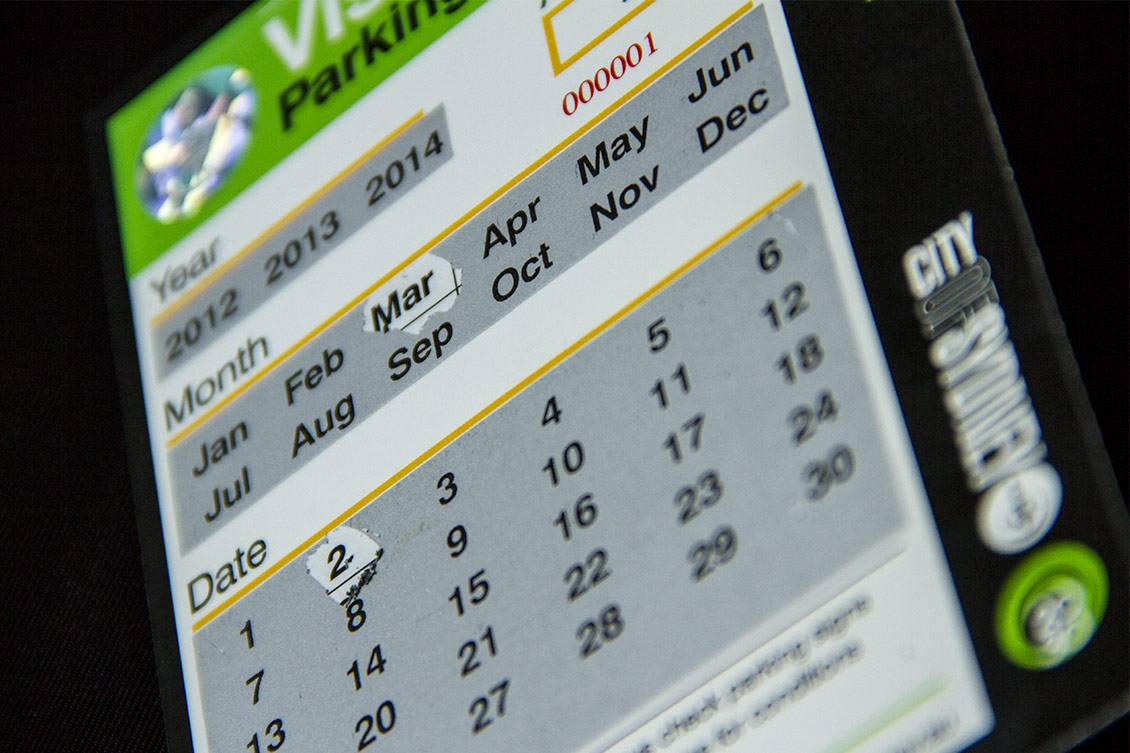

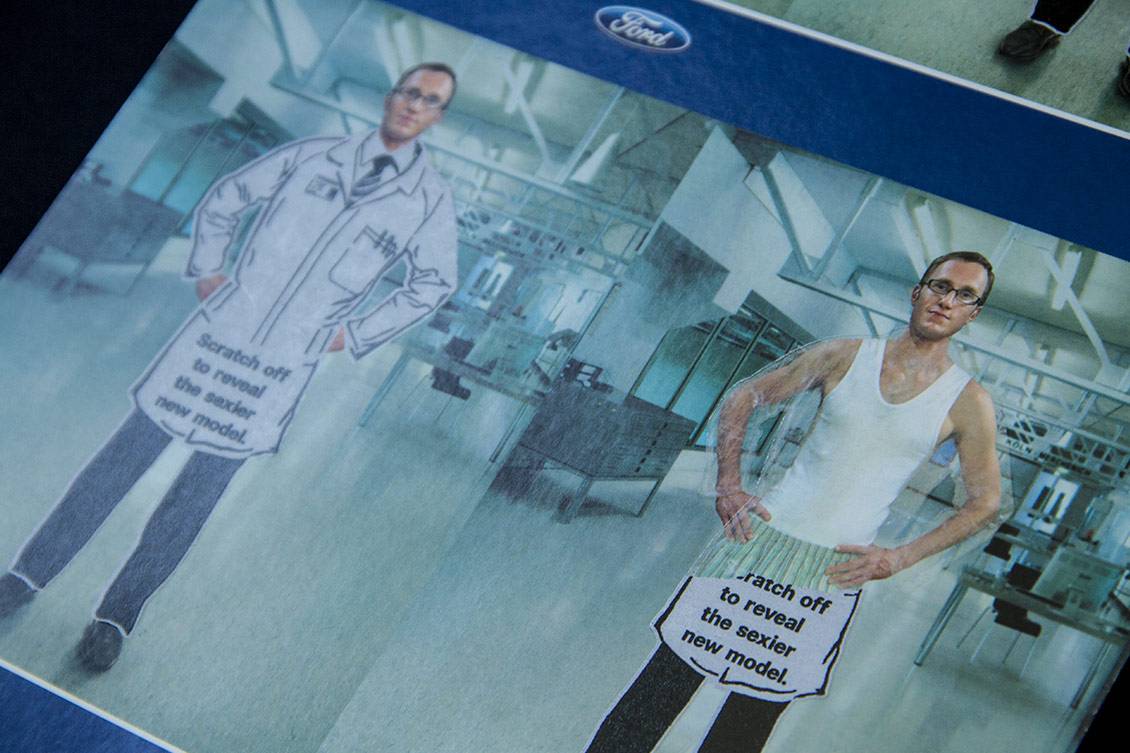

ScratchKote has many promotional activities associated with its use whether it’s from a supermarket chain, a shopping centre or your local pub/club the concept remains the same. ScratchKote works!! and it continues to be a product that will stand the test of time because of its unique and mystic qualities. The idea is that the customer scratches a panel on the surface of a printed ticket to reveal a hidden prize. It is used in lottery type situations and other promotions where customer awareness and brand loyalties are heightened through cash or free giveaways.

ScratchKote is available in silver and gold and yes we can provide a black overprint to the scratch area for further effect. Always remember that a release varnish will be required underneath the ScratchKote at all times. The release varnish acts as a barrier between the printed surface and the ScratchKote, therefore, allowing the product to be scratched off. Allkotes provides two options in a form of release varnish the first is our all over GlossKote or SpotKote gloss. These options allow scope for any writing that may be required on the scratch card using the SpotKote. The all-over GlossKote provides a glossy finish to the card or sheet.

DO'S

Plan your sheet wisely as some scratch card promotions include various prizes and it’s important they aren’t mixed up prior to sending to Allkotes. Quantity breakdown lists are a handy tip when producing various sheeted work, this will provide accurate counts for post-processing.

Should you choose a SpotKote release varnish its a good idea to supply your film or PDF stepped up accordingly with a nice tight fit regarding the registration. Then supply the second film or PDF file again stepped up while allowing a 2mm margin bigger all round, this will compensate for any movement during the ScratchKote process. It’s widely understood that tolerance levels of 0.5mm to 1mm are commercially acceptable for this process.

DONT'S

Should you wish to apply your own release varnish its strongly advised that you contact your ink or varnish supplier before you print. Allkotes is happy to assist in the testing of your release varnish, however, we will need to let your sheets sit for 48hours prior to testing. The varnish needs time to cure and each stock can act differently which can give a false reading.

The same can be said for any varnish, primer or aqueous varnish unless its approved by your ink or varnish supplier and tested by Allkotes prior to proceeding. Avoid excessive use of spray powder as this will affect the quality of the release varnish and the overall quality of the job.

Category

Products, Spot Coatings