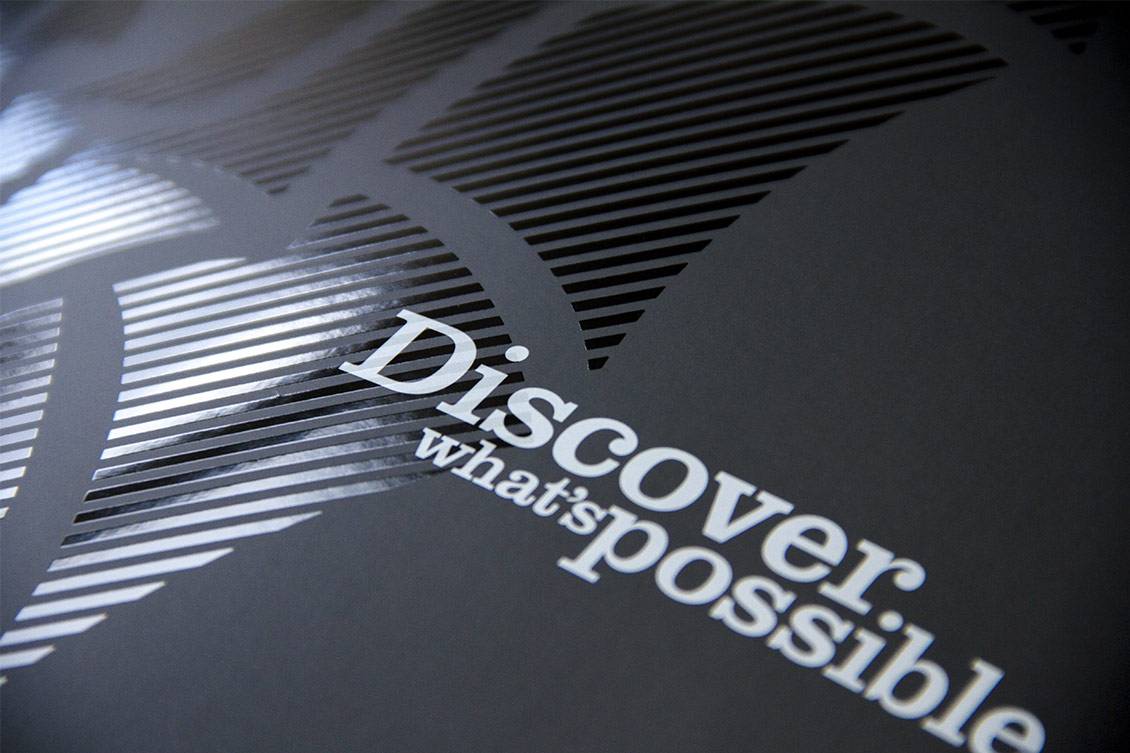

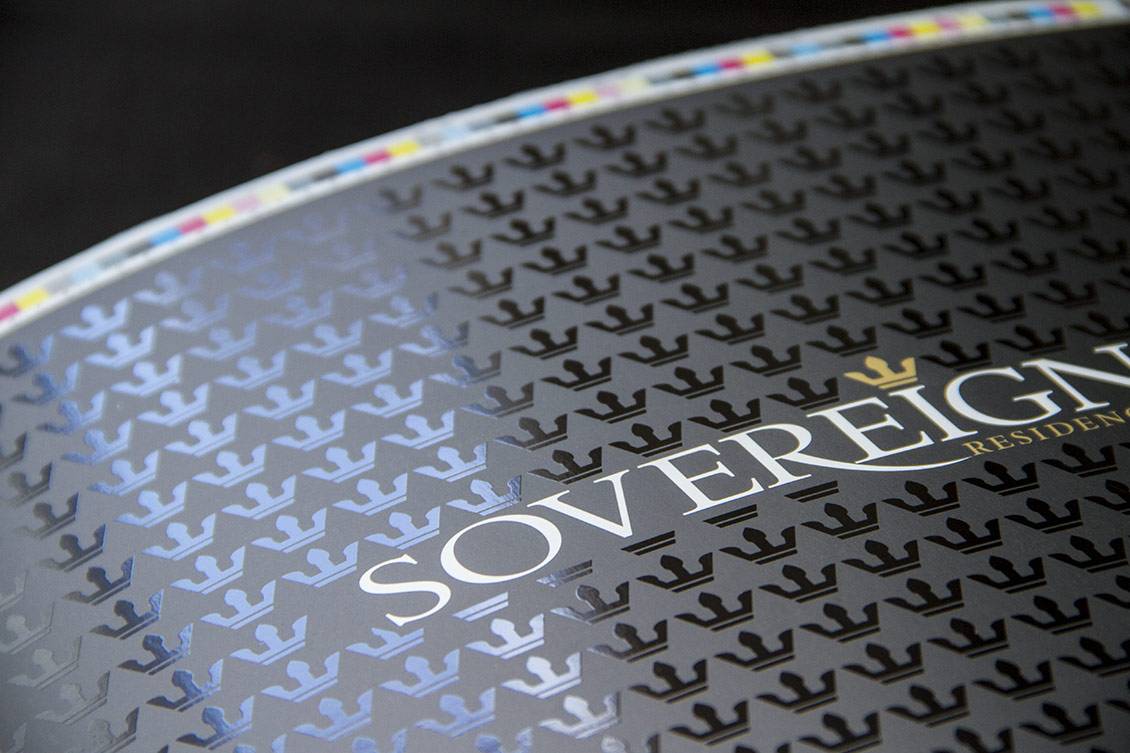

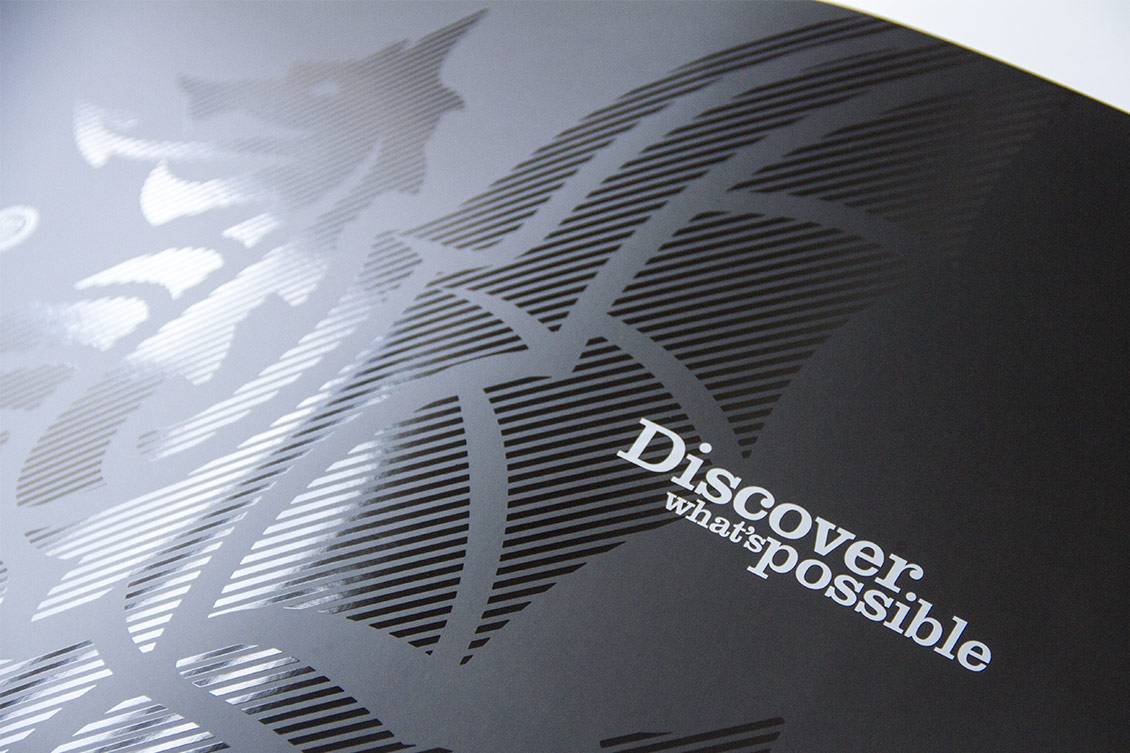

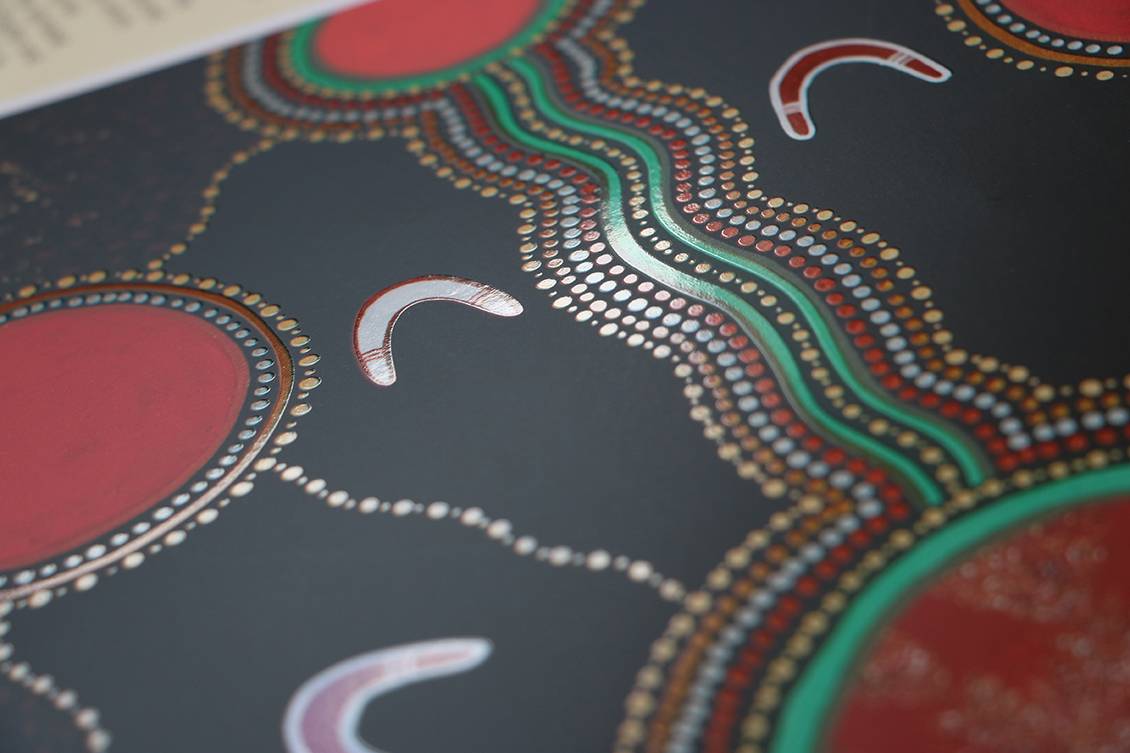

MatteKote & SpotKote have been a winning combination for a number of years. This fantastic combination still sets printed jobs apart and will continue to do so as today’s designers embrace the clever use of these two products. The attraction of a smooth silk matt finish with the striking contrast of a high SpotKote gloss finish to highlight logos, panels and special graphics and designs. A stunning way to enhance your print and the only limitation to the use of these two products together is your imagination. Don’t be afraid to add a Foil stamp, emboss, deboss or even BubbleKote for that extra bit of lift and texture.

MATTKOTE + SPOTKOTE

About This Project

DO'S

Remember this is a two-part process so you need to allow time for these products to be applied and cured before despatch. We require a film positive right reading emulsion up or a PDF file outlining the areas to be coated plus a 20mm grip is a strict requirement. Ensure your inks are dry before we laminate or coat otherwise set off, scuffing or marking may occur. Its advised that you check your file before sending to Allkotes as we will not be responsible for any errors or images that can drop off your PDF files. Each file you provide will require a film output and a screen charge so please ensure we are made aware at the quoting stage how many screens or sections may be required in completing your job.

DONT'S

When setting up your file please don’t provide halftones or vignettes without contacting your Allkotes team. In some cases, certain colours can burn out so it’s advised you contact your ink supplier before you print. Uncoated stocks have proven difficult to process and in some cases very disappointing in their results. Allkotes prefers not to SpotKote uncoated stocks unless prior testing has taken place and both parties are satisfied with the results. Avoid excessive use of spray powder as this will affect the overall quality of your job.

Date

20 November