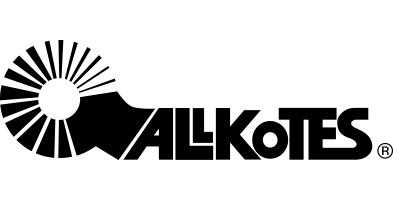

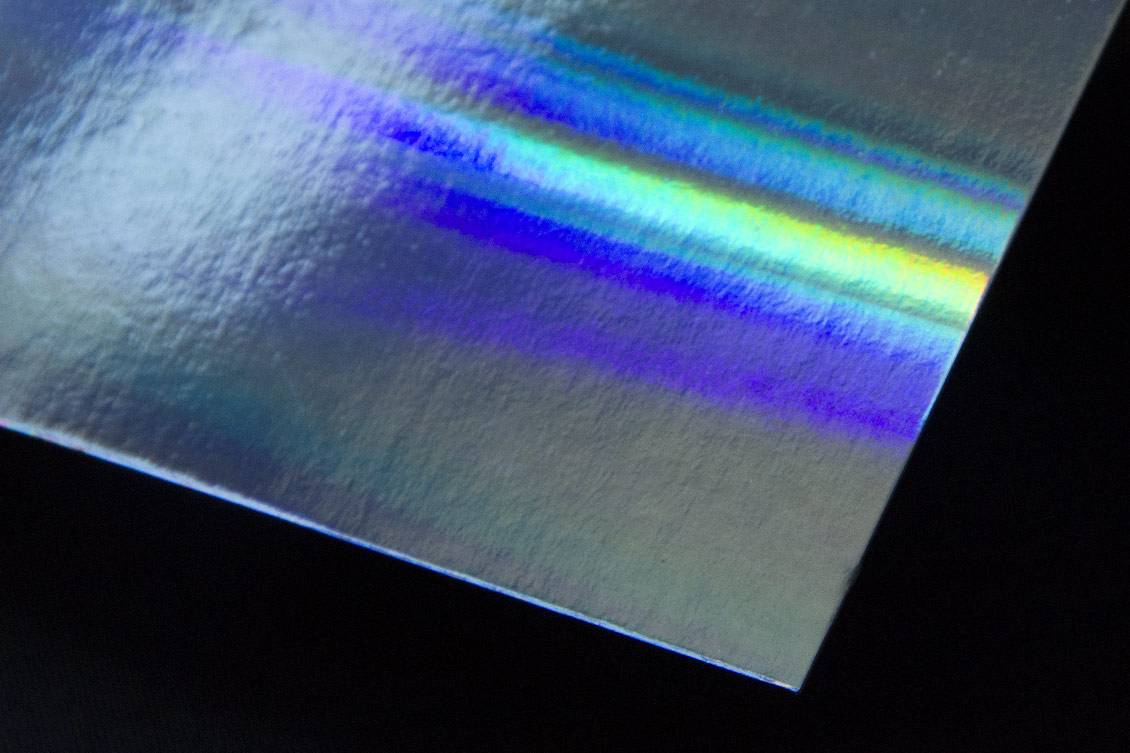

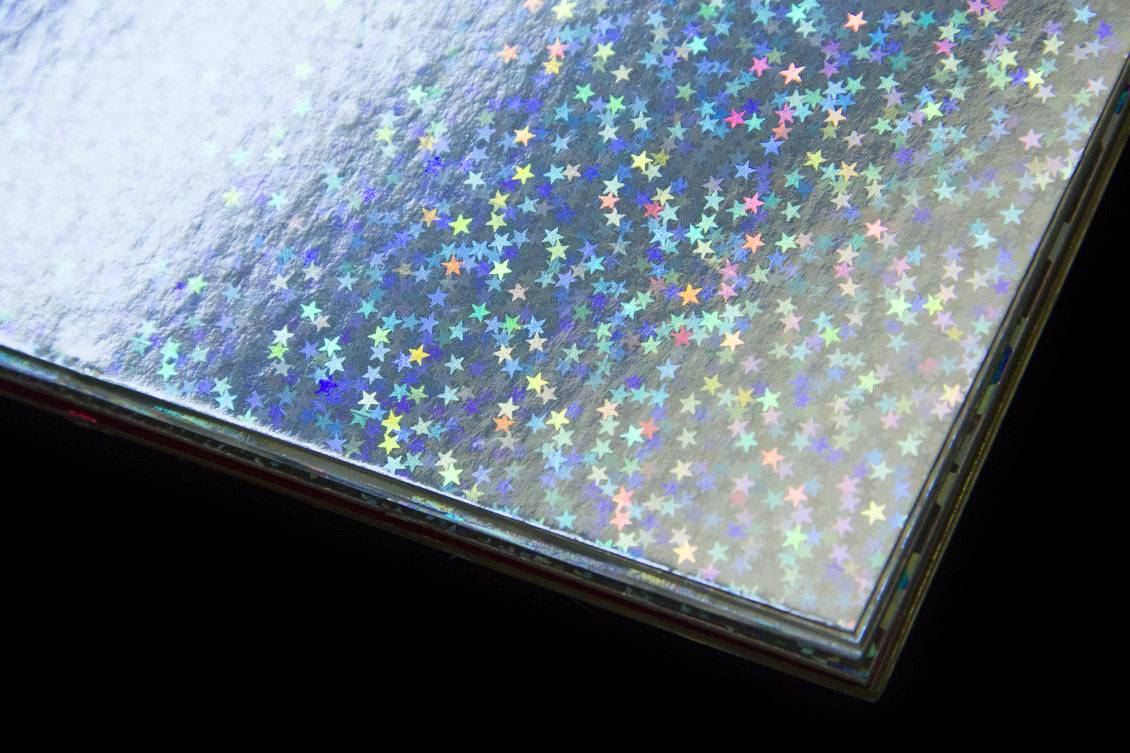

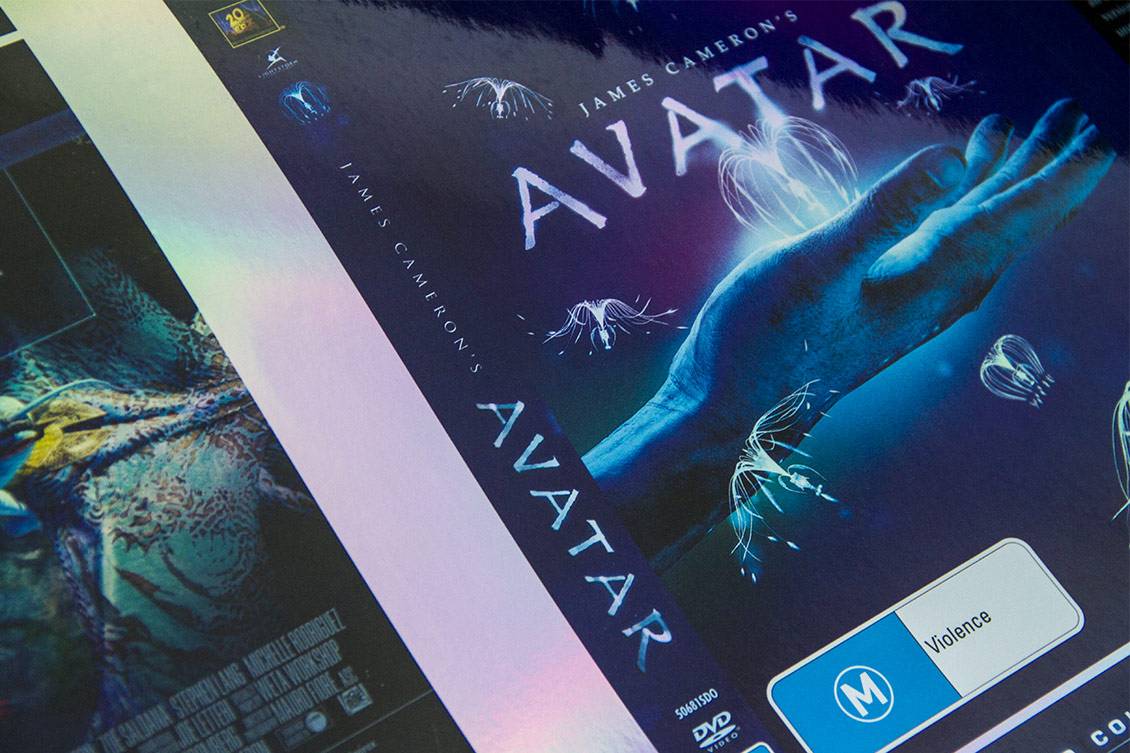

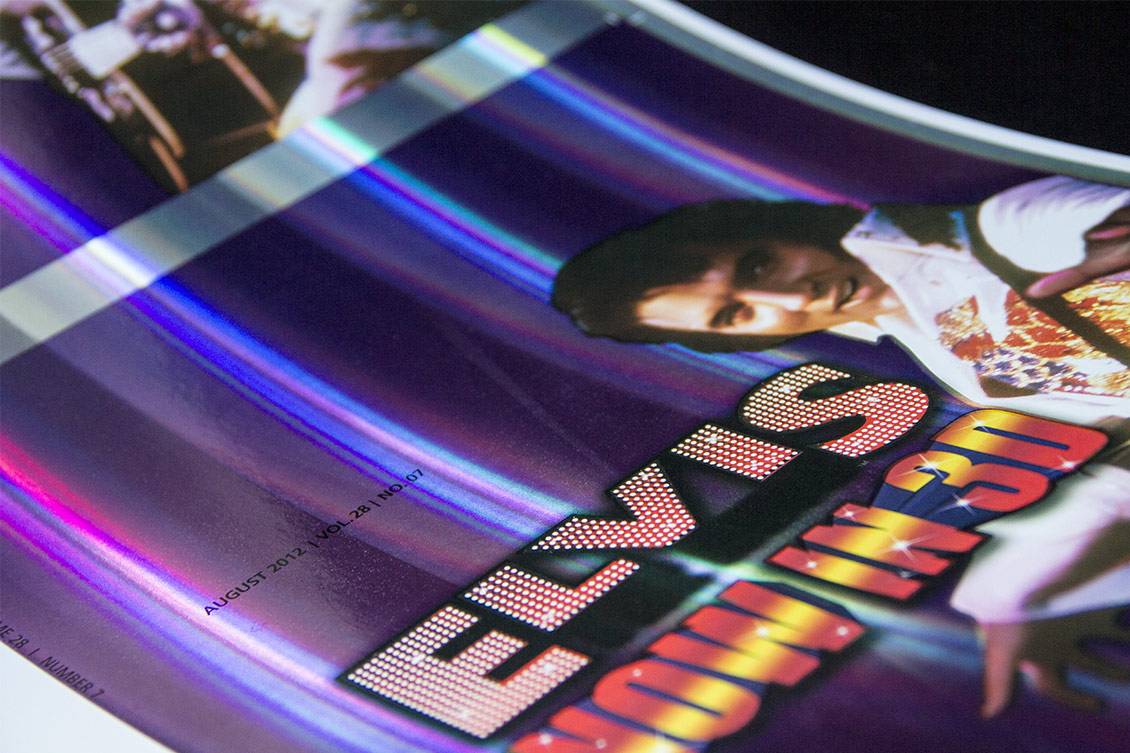

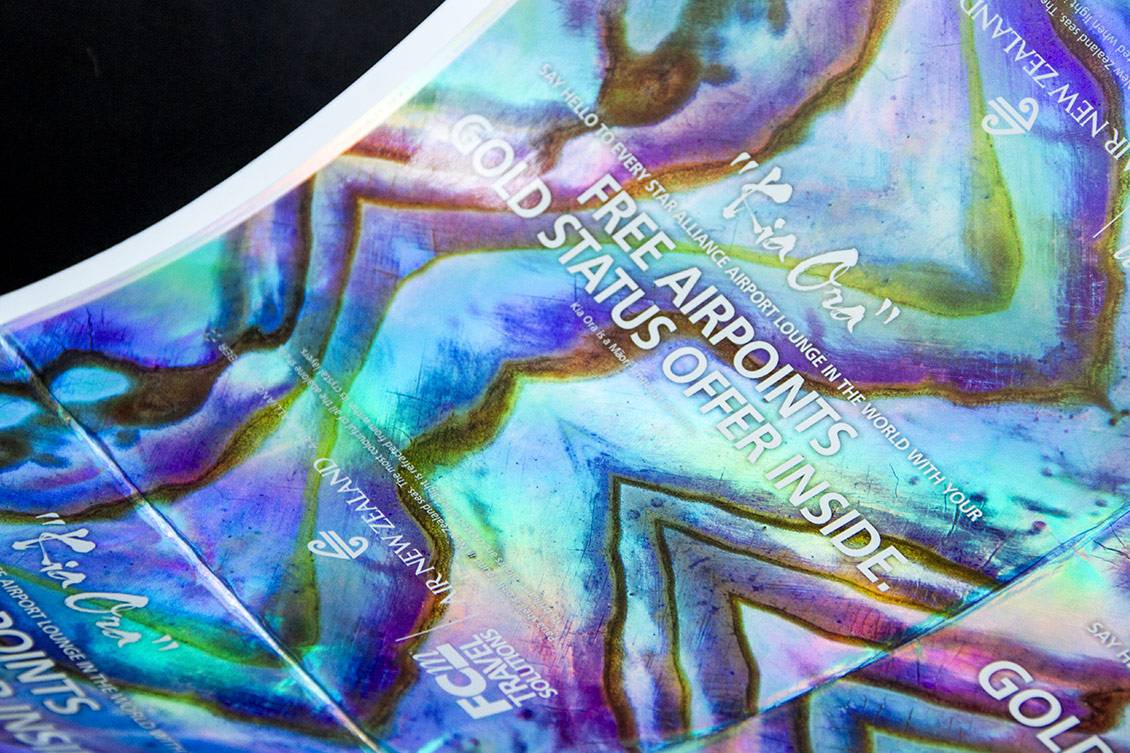

Our holographic films are part of our Mirra range of products there are a number of exciting designs and patterns with a metallised or clear finish for packaging, book and magazine covers, POS items or any other printed promotional material. We laminate your chosen holographic film to your supplied paper or board. Special or individual designs are available, but these are subject to lead times depending upon your requirements. Printing over holographic film requires the use of Foil/Vinyl, screen or UV inks we recommend you discuss with your ink supplier whats best for you. For that added protection to your print why not add gloss PlastaKote or KeyKote over the top. Current available patterns include stars, vector, cosmos, haze, shards, pillars, rainbow and coloured reflecta. Also available in select patterns are clear holographic films, contact your local Allkotes should you wish to see or know more about our holographic range.

HOLOGRAPHIC FILM

About This Project

DO'S

The quality of the paper or board you select can impact on the finish of the holographic film feel free to contact your Allkotes team to discuss your options. Metallised holographic film is opaque so when planning your next job remember the film will lay down first followed by your printing. (unless you are using a clear holographic film where the printing process will take place first) It’s a good idea to supply overs for us to set up on when running your sheets. Please provide a marked up sheet showing your preferred grip and lay. Some holographic films have patterns running in certain directions please ensure you have discussed this with your customer and your Allkotes team particularly at the quoting stage. Remember the holographic metallised or clear film is applied to the whole sheet.

DONT'S

Lighter weights of double-sided coated stocks can be susceptible to static issues during and after the lamination process. This, in turn, can create feeding issues during the printing process. Its recommended stock weights of 170gsm or higher are used and preferably coated one side only. Should you require any further advice please contact your Allkotes team.

Date

20 November